In the vast landscape of manufacturing, where precision and innovation converge, the realm of plastic injection mould manufacturing stands as a pinnacle of artistry and scientific prowess. Let’s delve into the captivating journey of crafting perfection through the intricate process of plastic injection mould manufacturing.

A Symphony of Design and Precision

At the heart of plastic injection mould manufacturing lies the harmonious symphony of design and precision. Moulds are not mere tools; they have meticulously engineered blueprints that determine the form, function, and quality of the end product. Every curve, every cavity, and every detail is carefully considered, resulting in moulds that are a masterpiece of geometrical accuracy.

From Concept to Creation

The journey begins with a concept—a product envisioned to meet a need or solve a problem. This idea transforms into a digital design, a virtual blueprint that guides the creation of the mould. Computer-aided design (CAD) software lends its power, allowing engineers to simulate and refine every aspect before embarking on the physical creation of the mould.

Meticulous Craftsmanship

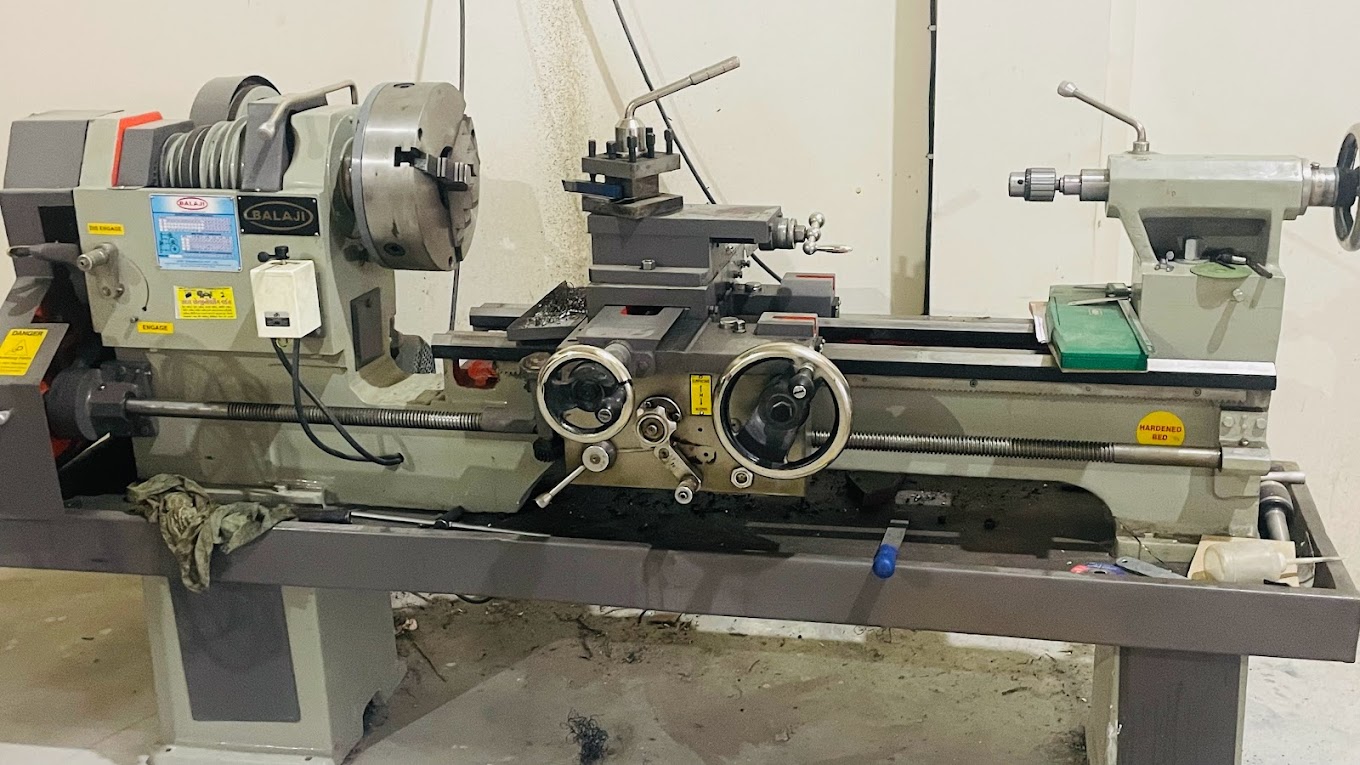

Crafting an injection mould is akin to sculpting with precision. Master mould makers utilize a mix of traditional craftsmanship and cutting-edge technology. Machining tools, electrical discharge machines, and 3D printing come together to shape raw materials into moulds that mirror virtual designs. This delicate dance of technology and human skill ensures that the moulds are not just accurate, but also durable and reliable.

Injection Moulding: Art in Motion

Once the mould is ready, it’s time for the star of the show: plastic injection moulding. This process involves injecting molten plastic into the mould’s cavities at high pressures. The plastic takes the form of mould, setting the stage for the creation of countless products that span industries—automotive, consumer goods, medical devices, and more.

Innovation and Adaptability

In the realm of plastic injection mould manufacturing, innovation and adaptability are constant companions. Advanced materials, optimized cooling systems, and novel techniques continuously push the boundaries of what’s possible. The industry evolves, embracing sustainable practices with biodegradable plastics and energy-efficient processes, reflecting a commitment to both progress and the planet.

Precision Meets Production

The culmination of this intricate process is not just a mould; it’s a gateway to mass production that upholds the standards of excellence set during its creation. The precision embodied in the mould translates into products that are uniform, reliable, and of the highest quality. This consistency fuels industries, empowers innovation, and enhances our daily lives.

Crafting Tomorrow, Today

As we reflect on the art and science of plastic injection mould manufacturing, we see a microcosm of human ingenuity. It’s the convergence of creativity and engineering, of design and precision, that brings forth products that shape our world. From the car you drive to the packaging that protects your purchases, plastic injection mould manufacturing is woven into the fabric of modern life.

So, the next time you hold a perfectly moulded object, remember that it’s a result of the meticulous craft that bridges artistry with science. Plastic injection mould manufacturing isn’t just about creating products; it’s about crafting perfection—one mould, one injection, and one masterpiece at a time.

Delve into the fusion of artistry and science at Hattrix Mould Craft. Our mastery in plastic injection mould manufacturing redefines perfection. With meticulous craftsmanship and cutting-edge technology, we sculpt ideas into flawless reality, setting benchmarks for precision and innovation.

For more information visit: https://www.hattrixmouldcraft.com/